| Painting System: | |||

|

Substrate

|

Primer ( 1 coat )

|

Intermediate ( 1 coat )

|

Topcoat ( 1 - 2 coats )

|

|

Ferrous Metal

(Interior Only) |

BENZIPOX Mastic 88 or EA9 Red Oxide Primer

|

BENZIPOX Mastic 88 or BENZIPOX 280

|

BENZIPOX 280

|

|

Non-Ferrous Metal (Interior Only)

|

BENZIPOX EA9 Red Oxide Primer or BENZi 100 Etching Primer

|

BENZIPOX Mastic 88 or BENZIPOX 280

|

BENZIPOX 280

|

|

Concrete Floor (Interior Only)

|

BENZIPOX Excel-Damp Primer

|

BENZIPOX Mastic 88 or BENZIPOX 280

|

BENZIPOX 280

|

5 litres & 15 litres

| Mixing Ratio (By Volume) | : 4 : 1 (Base : Hardener) |

| Color | : Assorted colors, refer Color Infinity & BENZi High Performance Coating color card |

| Film Finish | : High Gloss |

| Touch Dry | : 1 - 2 hours (depends on temperature and humidity) |

| Recoating Interval | : Minimum 6 hours |

| Solid Content | : 60% (by weight); 40% (by volume) |

| Dry Film Thickness | : 50 - 80 microns / coat |

| Theoretical Coverage | : 9 m2 / litre / coat (DFT of 50 microns); 6 m2 / litre / coat (DFT of 80 microns) |

| No. of Coat | : Minimum 2 coats |

| Application | : Brush, roller, air spray or airless spray |

| Thinning | : Use Thinner for dilution, dilute up to 5 - 10% if necessary |

| Cleaning Up | : Clean all paint equipment with Thinner immediately after use |

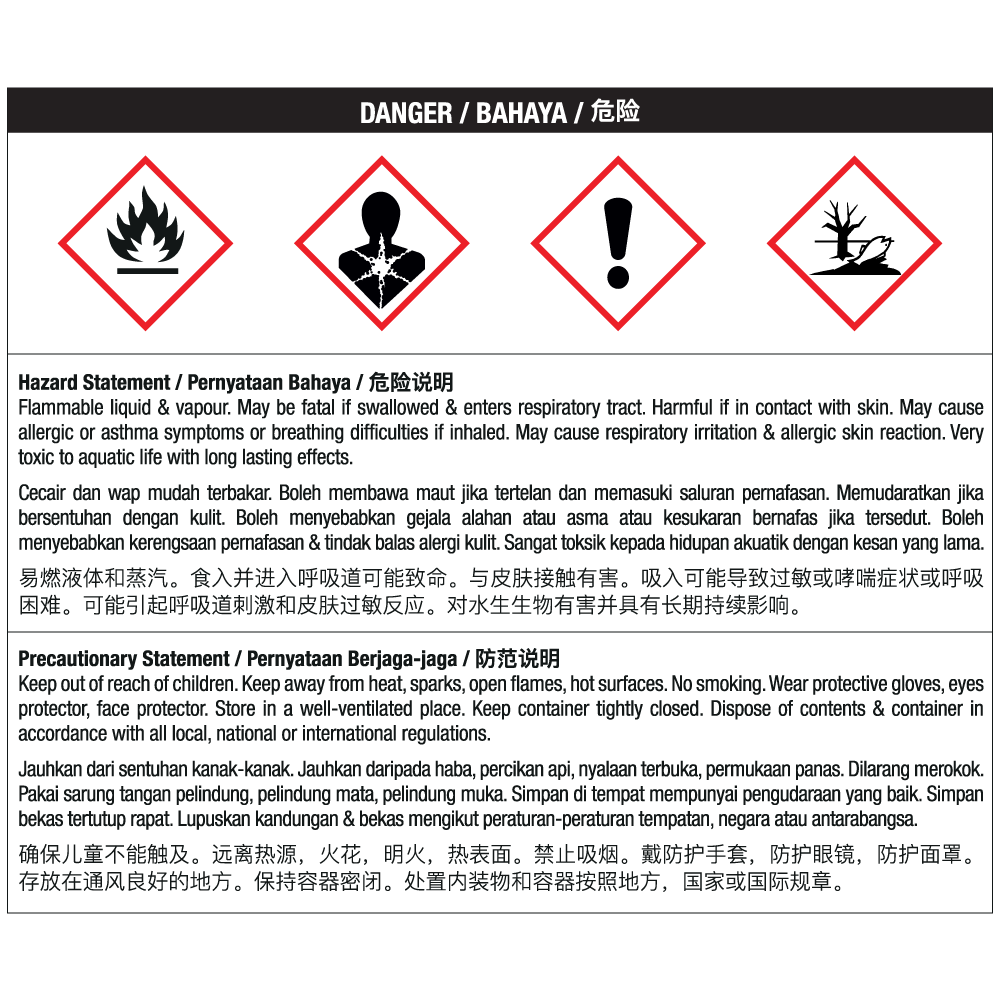

FLAMMABLE. During painting, make sure no source of ignition at surrounding and no smoking. When not in use, store paint in cool and shaded place and do not directly expose to sunlight. Allow proper ventilation and wear mask during painting. Do not breathe vapour or spray. Keep doors and windows open during application and drying. It is advisable to wear eye protector while applying. In case of contact with eyes, rinse immediately with plenty of water and seek medical treatment. To remove splashes of paint from skin, use suitable cleanser or soap and water. Do not dispose paint into drains or watercourses. Refer to MCI Paint Technical Data Sheet (TDS) for further details.

Materials Safety Data Sheet (MSDS) is available upon request.

Click link below to download

Technical Data Sheet (TDS)

Click link below to download

Color Infinity

BENZi High Performance Coating